Filter Cloths

for chamber, membrane, frame and drip-tight filter presses

SANIN

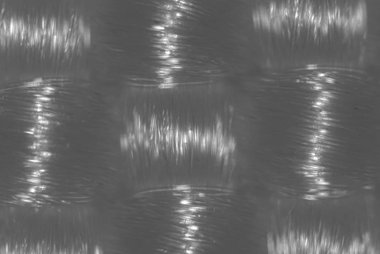

Monofil Filter Cloths

Threats used for the production of these qualities consist of continuous filaments or plastic wires respectively.

Properties: very little blockages, very high dry content, good cake release properties, long lifetime, easy to clean, best regenerative ability after washing

SANIN

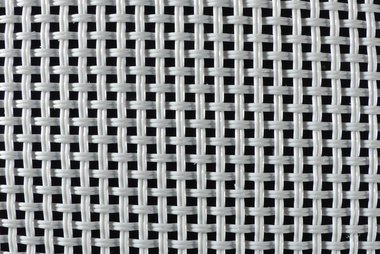

Filter Cloth Qualities Multifil

Multifil means, that the threats used during weaving consist of at least two continuous filaments. The number of fibers remains constant over the length of the threat.

Properties: increased abrasion resistance, high strength, retention of fine particles, high deposition rate

SANIN

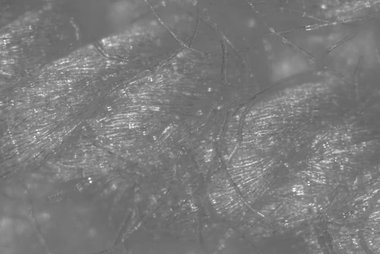

Staple Fiber Filter Cloths

Spinning threads, which are further processed to staple fibers and therefore restricted in length are the foundation of these filter cloths. After twisting them to a yarn they can be used in the weaving process.

Properties: excellent retention of fine particles, very good initial filtration with little or no clouded filtrate but a clear filtrate

SANIN

Monofil/multifil Filter Cloths or the like

Moreover different combinations of threats are possible during weaving. For instance, filter cloths made from fabrics which consist of monofil warp threads and multifil weft threads are often used.

Properties: A combination of the various portrayed ones

SANIN

Drainage Filter Cloths

The flow resistance of the filter cloth itself as well as of the filter cloth base is crucial. The flow rate of the filtrate is reduced where the medium lays on the supporting bars or knobs. Because of the lower effective filter surface, the filter cloth resistance increases. This problem can be dealt with by inserting drainage cloths between filter cloth and filter press element.

Properties: Reduction of flow resistance, lifetime extension, better cake drying, better cake release properties